Infrastructure

The Science of Load Distribution: Understanding Structural Behavior of Steel Decking

In modern construction, structural integrity is crucial for ensuring safety and longevity. One essential component that plays a vital role in supporting loads and distributing weight efficiently is steel decking. By understanding how load distribution works within steel decking systems, engineers, architects, and builders can optimize designs for strength, efficiency, and cost-effectiveness. This article delves into the science behind load distribution and the structural behavior of steel decking, emphasizing its benefits in various construction applications.

What is Load Distribution?

Load distribution refers to how forces applied to a structure are transferred and dispersed throughout its framework. In steel decking systems, this involves spreading loads—such as live loads (people, furniture, and vehicles) and dead loads (building materials and permanent fixtures)—across the supporting structure to prevent failure. Efficient load distribution ensures that no single area bears excessive stress, which could lead to structural weaknesses or collapse.

Structural Behavior of Steel Decking

Steel decking serves as both a structural element and a formwork system. Its behavior under load is influenced by several key factors, including material properties, deck profile, and the method of attachment to the supporting framework. The primary structural behaviors of steel decking include:

1. Composite Action with Concrete

When used in composite floor systems, steel decking acts as a reinforcement for the concrete slab. The combination of steel decking and concrete enhances load-bearing capacity by allowing both materials to work together. Steel resists tensile forces, while concrete handles compressive forces, creating a balanced load distribution system that increases the overall strength of the structure.

2. Flexural Strength and Stiffness

Steel decking is designed with corrugated or ribbed profiles, which increase its flexural strength and stiffness. This allows the decking to span longer distances with minimal deflection. The stiffness of steel decking also prevents excessive bending under heavy loads, making it a reliable option for floors, roofs, and mezzanines in commercial and industrial buildings.

3. Shear Bond Performance

The interlocking design of steel decking improves its shear bond performance with concrete, reducing slippage and enhancing structural stability. Shear studs and mechanical fasteners further strengthen the connection between the steel deck and supporting beams, improving the overall performance of the structure under various loading conditions.

Load Transfer Mechanisms in Steel Decking

Steel decking plays a crucial role in distributing loads through different mechanisms, including:

1. Vertical Load Transfer

Vertical loads, such as weight from people, furniture, and equipment, are transferred from the steel deck to the supporting beams and columns. The decking distributes these forces evenly to prevent localized stress concentrations that could compromise structural integrity.

2. Lateral Load Resistance

Lateral loads—such as those caused by wind, seismic activity, and dynamic forces—are resisted by the steel decking system in conjunction with shear walls, bracing, and structural frames. By providing lateral stability, steel decking helps buildings withstand external forces without excessive movement or deformation.

3. Axial Load Transfer

Axial loads are forces that act along the length of structural members, such as columns and beams. Steel decking contributes to axial load distribution by reinforcing load paths and ensuring that forces are efficiently transmitted to the foundation.

Advantages of Steel Decking in Load Distribution

The use of steel decking in construction provides several advantages that enhance load distribution and structural performance:

1. High Strength-to-Weight Ratio

Steel decking is lightweight compared to traditional concrete or timber alternatives, yet it offers exceptional strength. This allows for efficient load distribution without adding excessive weight to the structure, reducing foundation and support requirements.

2. Quick and Easy Installation

Prefabricated steel decking panels can be installed quickly, reducing construction time and labor costs. The precision engineering of steel decking systems ensures that load distribution remains uniform and predictable.

3. Cost Efficiency

Steel decking minimizes material wastage and requires less on-site labor, making it a cost-effective solution for builders and developers. Additionally, its durability reduces long-term maintenance costs, enhancing the overall value of construction projects.

4. Durability and Fire Resistance

Steel decking is resistant to corrosion, pests, and fire, making it a reliable choice for long-lasting structures. When combined with fire-rated coatings or concrete toppings, steel decking systems offer enhanced protection against structural damage and collapse.

Applications of Steel Decking in Load Distribution

Steel decking is used in various construction applications, including:

- Commercial Buildings: Steel decking is widely used in office buildings, shopping centers, and high-rises to provide strong, durable floors and roofs.

- Industrial Facilities: Factories, warehouses, and manufacturing plants rely on steel decking to support heavy equipment and large storage loads.

- Bridges and Infrastructure: In bridge construction, steel decking helps distribute traffic loads and withstand environmental stresses.

- Residential Construction: Multi-story residential buildings benefit from steel decking’s ability to support floors and balconies efficiently.

Future Innovations in Steel Decking Load Distribution

The construction industry continues to innovate in steel decking design and load distribution methods. Some emerging trends include:

- Advanced Material Coatings: New protective coatings enhance corrosion resistance and extend the lifespan of steel decking.

- Smart Structural Monitoring: Embedded sensors in steel decking systems provide real-time data on load distribution, allowing engineers to detect stress points and optimize structural performance.

- Sustainable Steel Decking: Environmentally friendly steel manufacturing processes and recycling initiatives reduce the carbon footprint of construction projects.

- Prefabricated Modular Solutions: Pre-assembled steel decking panels improve construction efficiency and ensure precise load distribution in modular building systems.

Conclusion

Understanding the structural behavior of steel decking is essential for optimizing load distribution in modern construction. By leveraging its composite action, flexural strength, and load transfer capabilities, builders can create safer, more efficient, and cost-effective structures. As innovations in steel decking continue to evolve, the industry will benefit from even more durable and sustainable solutions that enhance structural performance and long-term reliability. Whether in commercial, industrial, or residential construction, steel decking remains a cornerstone of modern engineering, bridging the gap between strength and efficiency.

-

Press Release6 days ago

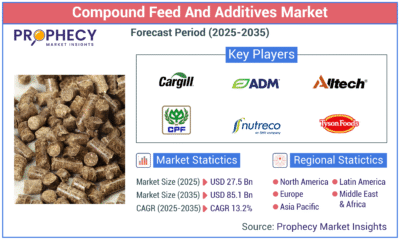

Press Release6 days agoGlobal Compound Feeds and Additives Industry Report: Market Expansion and Competitive Insights to 2035

-

Technology6 days ago

Technology6 days agoWhat to Know Before Switching Cell Phone Network Services in 2025

-

Press Release4 days ago

Press Release4 days agoCrypto WINNAZ Launches First On-Chain Yield Engine for Meme Coins, Enabling 20x–300x Returns

-

Press Release1 day ago

Press Release1 day agoBellarium ($BEL) Price Prediction: Could It Hit $5 by 2026?

-

Press Release1 day ago

Press Release1 day agoWhy Alaxio (ALX) Is a Top Pick for Smart Crypto Investors

-

Business13 hours ago

Business13 hours agoHow Managed IT Solutions Help Small Teams Compete at Enterprise Scale