Food

The Role of Proper Ventilation in Powder Coating Oven Operations

Powder coating ovens are essential in the powder coating process, as they cure the powder coating onto the surface of the object being coated. However, the process of curing the powder coating can release harmful fumes and gases into the air, making proper ventilation a crucial aspect of powder coating oven operations. In this blog post, we will discuss the role of proper ventilation in powder coating oven operations and why it is essential for the safety of workers and the environment.

Importance of Proper Ventilation

Proper ventilation is crucial in powder coating oven operations to ensure the safety of workers and the environment. The curing process of powder coating releases fumes and gases that can be harmful to human health and the environment. These fumes and gases can cause respiratory problems, eye irritation, and other health issues if inhaled. In addition, they can contribute to air pollution and harm the environment.

Types of Ventilation Systems

There are two types of ventilation systems that can be used in powder coating oven operations: dilution ventilation and local exhaust ventilation. Dilution ventilation involves the use of fans to circulate air in the workspace, diluting the concentration of fumes and gases. Local exhaust ventilation, on the other hand, involves the use of hoods and ducts to capture and remove fumes and gases at the source.

Dilution Ventilation

Dilution ventilation is a common method of ventilation used in powder coating oven operations. It involves the use of fans to circulate air in the workspace, diluting the concentration of fumes and gases. This method is effective in reducing the concentration of fumes and gases in the air, but it does not remove them entirely. Dilution ventilation is best used in large workspaces where the concentration of fumes and gases is low.

Local Exhaust Ventilation

Local exhaust ventilation is a more effective method of ventilation used in powder coating oven operations. It involves the use of hoods and ducts to capture and remove fumes and gases at the source. This method is more effective in removing fumes and gases from the air, but it requires more equipment and maintenance. Local exhaust ventilation is best used in small workspaces where the concentration of fumes and gases is high.

Proper Maintenance of Ventilation Systems

Proper maintenance of ventilation systems is essential in ensuring their effectiveness in powder coating oven operations. Regular cleaning and inspection of ventilation systems can prevent the buildup of dust and debris, which can reduce their effectiveness. In addition, regular maintenance can ensure that ventilation systems are working correctly and are not releasing harmful fumes and gases into the air.

Compliance with Regulations

Proper ventilation in powder coating oven operations is not only essential for the safety of workers and the environment but also for compliance with regulations. The Occupational Safety and Health Administration (OSHA) has established regulations for the use of ventilation systems in the workplace. Compliance with these regulations is necessary to avoid fines and penalties and to ensure the safety of workers.

Conclusion

In conclusion, proper ventilation is crucial in powder coating oven operations to ensure the safety of workers and the environment. Dilution ventilation and local exhaust ventilation are two methods of ventilation that can be used in powder coating oven operations. Proper maintenance of ventilation systems is essential in ensuring their effectiveness, and compliance with regulations is necessary to avoid fines and penalties. By implementing proper ventilation systems and maintenance procedures, powder coating operations can be conducted safely and efficiently.

-

Press Release3 days ago

Press Release3 days agoNura Labs Files Revolutionary Patent: AI-Powered Wallet Solves the $180 Billion Crypto Staking Complexity Crisis

-

Press Release1 day ago

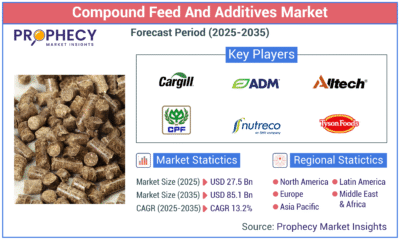

Press Release1 day agoGlobal Compound Feeds and Additives Industry Report: Market Expansion and Competitive Insights to 2035

-

Technology1 day ago

Technology1 day agoWhat to Know Before Switching Cell Phone Network Services in 2025