Home Improvement

Roofing Underlayment Requirements And It’s Importance

A lot of the rooftop systems of any house has a lot of seams. This is much true when the rooftop is made from the traditional shingles. There is a layer of protection installed between the shingles and the house, and it is called the roof underlayment. This is a waterproof and water-resistant barrier that is directly installed on the roofing deck. Why? Well, the answer is simple; it adds a layer of protection from the adverse weather condition.

Why Do I Need Roof Underlayment?

If you are thinking that you live in Houston, and you do not need roof underlayment, then perhaps you are wrong. The roofing underlayment is a moisture barrier, and every house needs to have one.

Note: Every house needs a roof underlayment. The only difference is that roofing underlayment requirements for other areas might be different.

Keep in mind that the underlayment of the roof provides the rooftop with an extra layer of protection from a lot of external elements that shingles cannot withstand all alone. The shingles have their own purpose; they reflect the rays of the sun, the block rainfall from entering the house. In short, they’re the first line of defense. But do you think that the shingles are also sealed at all the corners of the roof?

During strong winds, the shingles can be lifted from the side, which makes them vulnerable by a lot. So, if you want to protect the roof from all the external elements and the weather conditions, you need to have a roofing underlayment installed. Just make sure that you do not hire inexperienced and cheap roofing companies in Houston for the job.

Different Types Of Roof Underlayment

If you search the market, you’ll be to find that there are three basic kinds of roofing underlayment. After reading this section, you will be able to understand your own roofing underlayment requirements and opt for the one that you think is the most suitable for your rooftop.

Black-Top Saturated Felt

Built from natural or fiberglass materials, felt underlayment is water-safe, yet not 100% waterproof. Contractual workers normally install 15-or 30-pound felt on rooftops; the heavier the believed, the more impervious to damage during installation of the rooftop material, and the more extended the life expectancy.

The asphalt-soaked felt was one of the most well-known and broadly utilized kinds of underlayment before different kinds picked up footing. Produced using refined unrefined petroleum buildup, the asphalt viably repulses water and gives additional climate security; it likewise brags included imperviousness to fire and water damage control. Be that as it may, on the grounds that it tears effectively and doesn’t perform well under UV beams or heat, roofers are starting to eliminate it for better-quality underlayment.

Rubber Treated Asphalt

Utilized for a wide range of uses including concrete, rubber treated black-top is a hard, versatile elastic-like material that many think about ideal for roof underlayment. Clung legitimately to the decking without nails, it can make an unbending seal get water far from the decking. Rubber treated black-top is self-following and highlights a strip off layer to seal rooftop clasp better.

Known for predominant climate and dampness obstruction, it likewise has non-slide properties to make the installation process simpler for contractual workers. Also, rubber treated asphalt is exceptionally heat resistant, making it the ideal underlayment for rooftops in regions that experience outrageous heat.

Rubber treated asphalt is made of a key fixing called bitumen, which is well known in both commercial and residential roofing applications. For better quality and versatility, bitumen is now and again handcrafted to give the material explicit properties. Property holders and contractual workers like it for its toughness, climate obstruction, waterproof nature and protection from warm stun. It won’t split or become fragile because of sweltering or cold temperatures; it can withstand hail and other extraordinary climate conditions and is exceptionally impervious to UV beams.

Non-Bitumen Synthetics

Lightweight and tough, engineered materials can grasp the decking and the shingles firmly, which decreases sliding and is more appropriate for rooftops with more extreme inclines. Made from polypropylene or polyethylene strands, fabricated materials are famous on the grounds that they’re lightweight yet solid and furthermore impervious to the components and creepy crawlies.

Since they don’t assimilate dampness, artificial materials aren’t inclined to form and green growth development and are impervious to UV harm. This is both an uncommon and exceptionally desired element in each material framework, on the grounds that most rooftop harm originates from dampness. One drawback, nonetheless, is that engineered underlayment requires exact establishment, and if inappropriately introduced, may neglect to fill its need. Make certain to enlist a contractual worker that is ensured to install such sort of roofing material.

Final Words

As mentioned above, the roofing underlayment requirements will vary from person to person and area to are. You should always consider each factor prior to making a sound choice.

-

Press Release4 days ago

Press Release4 days agoClinical Trials Market Set for Robust Growth, Driven by Drug Development Surge and Digital Innovation

-

Press Release5 days ago

Press Release5 days agoFill-Finish Pharmaceutical Contract Manufacturing Market Expected to Flourish Amid Biopharmaceutical Boom and Global Outsourcing Trend by 2035

-

Press Release7 days ago

Press Release7 days agoBellarium ($BEL) Price Prediction: Could It Hit $5 by 2026?

-

Business6 days ago

Business6 days agoHow Managed IT Solutions Help Small Teams Compete at Enterprise Scale

-

Press Release5 days ago

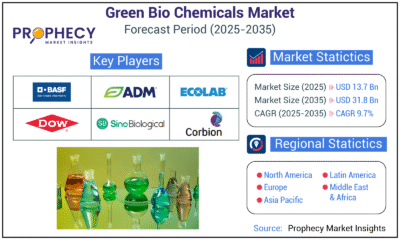

Press Release5 days agoGreen Bio Chemicals Market Poised for Sustainable Growth amidst Global Shift to Eco-Friendly Alternatives by 2035

-

Press Release5 days ago

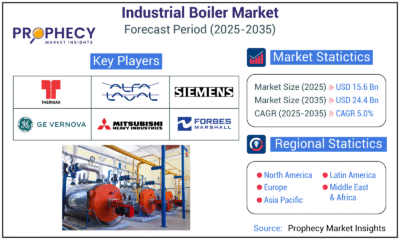

Press Release5 days agoIndustrial Boiler Market Expected to Surpass USD 24.4 Billion by 2035 Amid Growing Demand for Energy Efficiency and Industrialization

-

Press Release5 days ago

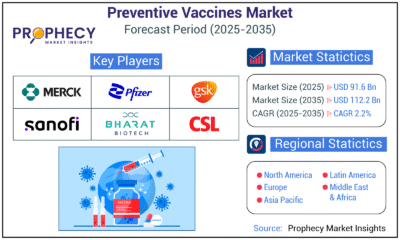

Press Release5 days agoPreventive Vaccines Market to Witness Strong Growth by 2035

-

Press Release5 days ago

Press Release5 days agoPet Food Nutraceutical Market Set for Robust Expansion Amid Rising Demand for Pet Wellness by 2035