Business

Key Rules and Standards for Boiler Maintenance and Safety Compliance

Boilers are integral to many industrial and commercial operations, providing essential heating and hot water capabilities. However, ensuring their safe and efficient operation requires adherence to stringent rules and standards for boiler maintenance and safety compliance. Whether you oversee a facility with multiple boilers or are responsible for a single boiler system, understanding these regulations is crucial for maintaining operational reliability and safeguarding against potential hazards.

Importance of Boiler Maintenance

Regular boiler maintenance not only prolongs the lifespan of equipment but also minimizes the risk of accidents, breakdowns, and costly repairs. Proper maintenance ensures that boilers operate efficiently, reducing energy consumption and optimizing performance. Additionally, adherence to safety standards protects personnel and premises from potential hazards associated with boiler operation.

Key Rules and Standards for Boiler Maintenance

Regular Inspections: Conduct regular inspections of boilers to identify wear, corrosion, leaks, or other potential issues. Inspections should be performed by qualified personnel and comply with jurisdictional regulations and industry standards.

Water Treatment: Implement an effective water treatment program to prevent scale buildup and corrosion within the boiler system. Proper water chemistry management extends equipment life and maintains efficiency.

Pressure and Temperature Controls: Ensure that pressure and temperature controls are functioning correctly to prevent overpressure situations that could lead to boiler failure or explosions.

Combustion Efficiency: Monitor and maintain combustion efficiency to optimize fuel consumption and reduce emissions. Periodically inspect and clean burners, fuel nozzles, and combustion chambers as part of routine maintenance.

Safety Valves: Test and verify the operation of safety valves regularly to ensure they relieve excess pressure safely. Safety valves are critical components for preventing overpressure incidents.

Ventilation and Air Supply: Ensure proper ventilation and adequate air supply for combustion to prevent the buildup of carbon monoxide and ensure safe operation.

Emergency Procedures: Establish and communicate clear emergency procedures for boiler shutdown, evacuation, and response to potential hazards. Conduct regular drills to ensure personnel are prepared to respond effectively in emergencies.

Compliance with Codes and Standards: Adhere to local jurisdictional codes, such as ASME Boiler and Pressure Vessel Code (BPVC) in the United States, and international standards such as ISO 9001 for quality management and ISO 14001 for environmental management.

Implementing a Maintenance Schedule

Developing a comprehensive maintenance schedule is essential for ensuring compliance with safety standards and prolonging the life of boiler systems:

Routine Maintenance: Schedule routine tasks such as cleaning, lubrication, and inspection of boiler components.

Scheduled Shutdowns: Plan scheduled shutdowns for thorough inspection, cleaning, and maintenance procedures that cannot be performed during normal operation.

Documentation and Records: Maintain detailed records of inspections, maintenance activities, repairs, and compliance with regulatory requirements. Documentation provides a historical record of boiler performance and facilitates audits and inspections.

Training and Education

Invest in training and education for personnel involved in boiler operation and maintenance:

Operator Training: Ensure boiler operators are trained in safe operating practices, emergency procedures, and routine maintenance tasks.

Continuing Education: Keep abreast of advancements in boiler technology, safety standards, and regulatory changes through ongoing education and professional development.

Conclusion

Adhering to rules and standards for boiler maintenance and safety compliance is essential for protecting personnel, property, and the environment while optimizing operational efficiency. By implementing a proactive maintenance program, following regulatory guidelines, and investing in training, organizations can mitigate risks associated with boiler operation and ensure long-term reliability. Prioritize safety, efficiency, and compliance to safeguard your boiler systems and achieve optimal performance in industrial and commercial applications.

For expert guidance on establishing a comprehensive boiler maintenance program tailored to your specific needs and regulatory requirements, consult with qualified professionals who specialize in boiler operations and safety compliance.

-

Press Release5 days ago

Press Release5 days agoNura Labs Files Revolutionary Patent: AI-Powered Wallet Solves the $180 Billion Crypto Staking Complexity Crisis

-

Press Release3 days ago

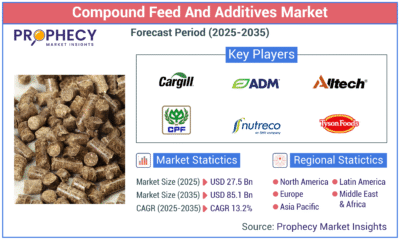

Press Release3 days agoGlobal Compound Feeds and Additives Industry Report: Market Expansion and Competitive Insights to 2035

-

Technology3 days ago

Technology3 days agoWhat to Know Before Switching Cell Phone Network Services in 2025

-

Press Release2 days ago

Press Release2 days agoCrypto WINNAZ Launches First On-Chain Yield Engine for Meme Coins, Enabling 20x–300x Returns