Business

Why Install EPDM Gaskets For The Prime Output Of Your Machine

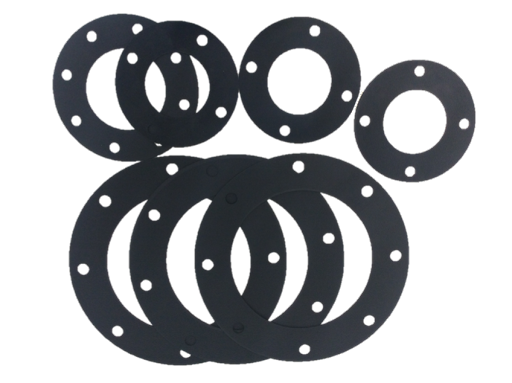

You might have noticed the small rubber circles that are used in most of the appliances. Though small in size, these EPDM gaskets are vital for the optimal functioning of the devices. These rubber seals are made of quality materials that are durable and resistant to many environmental calamities. They act as a seal and make sure the content inside the machine does not leak out. They are easy to install and can be repaired efficiently, which makes them a highly reliable accessory. Their versatility and affordability make them a popular choice among engineers, manufacturers, and contractors. Here are some of the reasons why using gaskets can ensure the proper operation of your device.

Benefits of installing EPDM gaskets

Chemical Resistance

Because of their superior chemical resistance, EPDM gaskets are frequently chosen in industrial applications. They can withstand being exposed to a variety of chemicals, such as acids, alkalis, and oils. They are therefore perfect for use in refineries, chemical processing facilities, and other fields where chemical resistance is essential.

High-Temperature Resistance

Additionally, these gaskets are very resistant to high temperatures. They retain their mechanical and elastic properties up to 150 °C (302 °F) without degrading. This characteristic makes them perfect for use in engine compartments, power plants, and HVAC systems, among other places where a high amount of heat is released.

Efficient UV Resistance

Due to their exceptional UV resistance, EPDM gaskets are perfect for use in outdoor applications. They can endure prolonged exposure to direct sunlight without deteriorating or losing their performance characteristics. Moreover, these accessories are perfect for use in roofing systems, outdoor lighting, and other outdoor applications because of this characteristic.

Effective against Ozone and Weathering

The gaskets offer excellent ozone and weathering resistance. They can be exposed to the weather, including wind, rain, and snow, without suffering damage or losing their performance capabilities. Due to this quality, they are perfect for use in exterior applications like roofing systems and door and window seals.

Electric Insulation

Excellent electrical insulation qualities can be found in EPDM gaskets. These parts remain unaffected by even large amounts of electrical current and can withstand high voltage. They are the perfect choice for use in switches and other electrical equipment because of this characteristic.

Easy to Install

Gaskets are extremely easy to install and low maintenance. Being lightweight and flexible, they are quite simple to handle. They are a great option for applications where downtime needs to be kept to a minimum because they also require little maintenance.

Low Compression Set

Due to their low compression set, the gaskets can keep their shape and seal even after extensive use. They are the best choice for static sealing applications because they allow the gasket to be compressed and held in place for extended periods of time.

Food Grade Material

EPDM gaskets are non-toxic and food-grade compliant, making them ideal for use in the food and beverage industry. They are suitable for use in the dairy industry because they are resistant to both animal and vegetable oils.

Versatile Material

A variety of sizes and shapes can be moulded into gaskets to fit a variety of applications. Due to their adaptability, they are perfect for use in a variety of fields, including plumbing, construction, aerospace, and the automotive industry.

Conclusion

Due to their exceptional qualities, EPDM gaskets are a flexible and affordable choice for a variety of applications. They are widely used in many industries for their exceptional properties like high-temperature resistance, weather resistance, chemical resistance, low compression set, and excellent electrical insulation. They deliver dependable and long-lasting performance in sectors like plumbing, aerospace, and automotive.

-

Stock Market6 days ago

Stock Market6 days agoUS-China Tariff Cuts Ignite Stock Market Surge

-

Stock Market5 days ago

Stock Market5 days agoUS Stock Market Soars as Tariff Cuts Signal Trade War Thaw

-

Cybersecurity2 days ago

Cybersecurity2 days agoIs Your Privacy at Risk? What You Need to Know About New Data Regulations in 2025

-

Business5 days ago

Business5 days agoTrump’s Middle East Tour: Economic Gains and Diplomatic Challenges

-

Politics6 days ago

Politics6 days agoSupreme Court Weighs In On Trump’s Birthright Citizenship Challenge

-

Digital Privacy2 days ago

Digital Privacy2 days agoThe Biggest Data Breaches of 2025 – And How to Protect Yourself

-

Finance4 days ago

Finance4 days agoUS Credit Rating Takes a Hit: Moody’s Downgrades to Aa1 Amid Debt Concerns

-

Home & Family4 days ago

Home & Family4 days agoHow Smart Homes Are Transforming the Way We Live in 2025